History

Yetsan Auto Radiator was founded by three brothers in Corum, Turkey early in 1970’s. They started the business with repairing radiators and making some metal work.

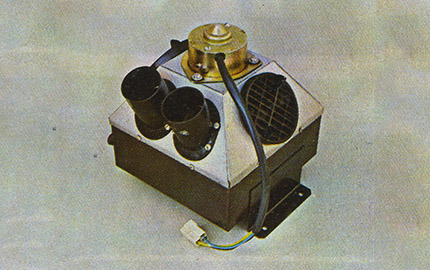

And in the following years they started to produce unique heating systems for cars and truck. After the serial production of the cabin heating systems company started to manufacture copper-brass heater cores for cabin heating system.

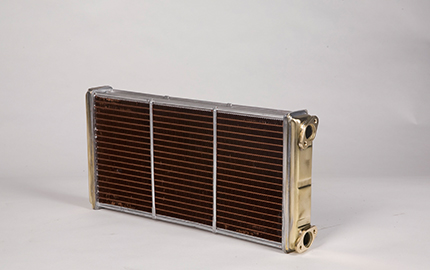

In 1990 company made new inwestments in order to manufacture new cabin heaters and copper brass heat exchangers. In 2007 in addition to our copper brass heat exchanger production we started to manufacture aluminum radiators and charge air coolers with the use of the most up-to-date production technologies.

Yetsan Auto Radiator A.S, Corum, is a systems partner of the international automotive industry. A specialist for engine cooling systems. Currently, Yetsan employs some 285 staff at 3 production sites.

Yetsan creates highly engineered heating and cooling systems for the following markets;

- 1. light, medium, and heavy-duty vehicles,

- 2. agriculture and forestry

- 3. construction and mining

- 4. industrial equipment

- 5. railways

- 6. special vehicles

- 7. gensets

Today, we advance the legacy of our founders by developing and manufacturing state-of-the-art cooling systems. As a leader in heating and cooling technology, we partner with our customers to provide solutions to cooling challenges. This market driven approach and our commitment to research and development will ensure our continued leadership in the thermal field for our customers with the following products;

- 1. Charge air coolers (bar&plate or tube&fin construction)

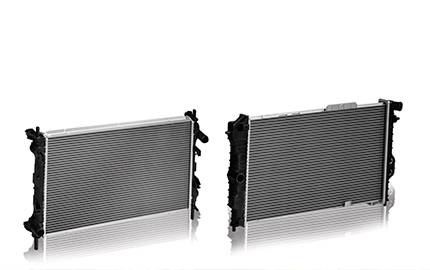

- 2. Radiators (bar&plate or tube&fin construction)

- 3. Oil coolers (bar&plate or tube&fin construction)

- 4. Heater cores

- 5. Operator cabin HVAC components

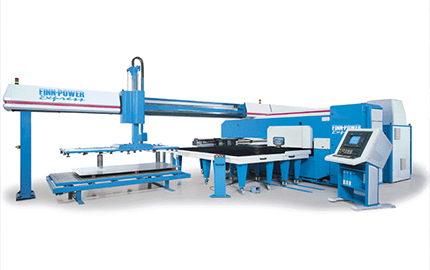

We are also applying new technology in our manufacturing operations, which brings us new processes and equipment to ensure quality and reduce costs, while also providing us with the flexibility for new business. For example, our plant in Ankara, Turkey utilizes the latest manufacturing technologiesin daily operations.

by Veysel Yetik and brothers in Corum as a small repair shop

of hand made engine cooling fans

Started the production of radiator curtains which was used in front of the truck radiator in the winter time to protect the radiator coolant from freezing.

Started the production of fuel reservior tanks for truck and busses during oil crisis.

Production of auxiliary heaters started for car, bus and truck.

Copper-brass heater core production started only for Yetsan cabin heaters.

Copper-brass radiator production for after market only.

First generation cabin heater systems with turbo fan systems.

Production of transmission oil cooler started.

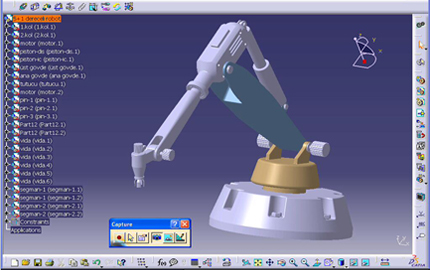

Engineering department started to use Unigraphics v17 software.

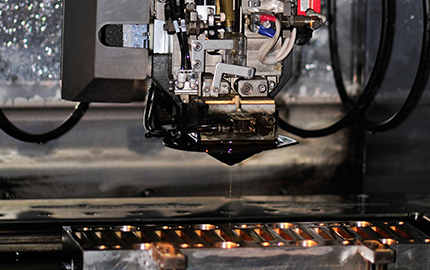

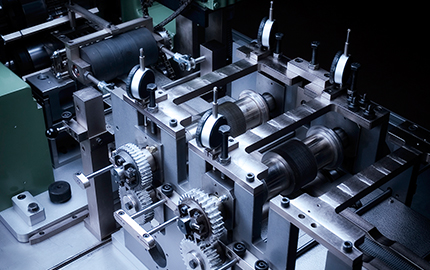

CNC controlled punch machines started operation

CNC controlled wire edm machines started to cut precise steel parts in the tooling department

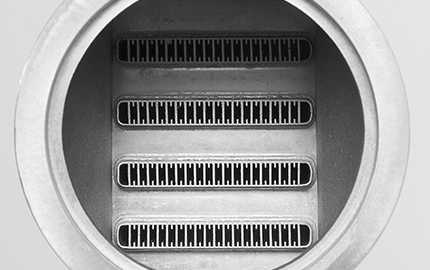

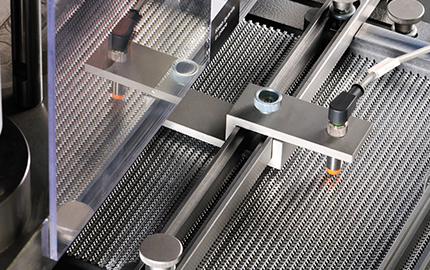

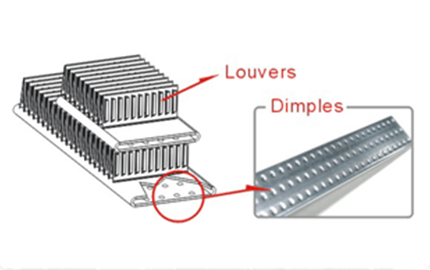

High speed copper and aluminum fin machine started to produce louvered-serpentine fins and turbulator fins

Fully automatic punch press machine started to run in the metal fabrication area

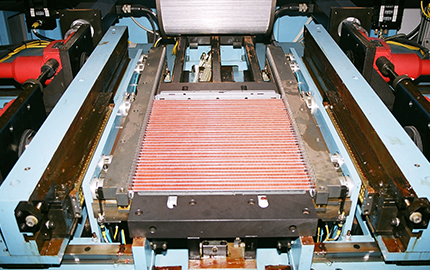

Production of aluminum brazed radiators started with the help of state of the art of machinery

Production of charge air cooler started.

First heavy duty radiator produced for BTR-80 personal carrier.

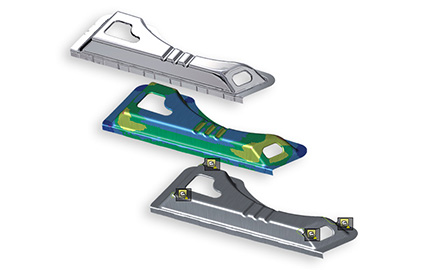

Started to use Sheet metal analysis software, Autoform, by engineering department.

Second Wire EDM machine started to cut hardened steels in the tooling department.

Firts aluminum intercooler with extruded tubes was produced.

Oil cooler turbulator machine was purchased for production of bar and late oil cooler.

Welded aluminum tube mill started to produce radiator and intercooler tubes. Capacity 100m/min.

Serial production of bar&plate oil coolers started.

High speed intercooler turbulator fin machine started to produce off-set fins.

Two large size core builders started to manufacture cores up to 1 meter by 1 meter.

Production of aluminum brazed heat cores started.

Two new robotic welding cells for charge air cooler and oil cooler production lines.

Started to supply cooling modules for wide-variety of machines that comprise the Off-Highway market

Production of radiators and charge air coolers in aluminum package design for military special vehicles.

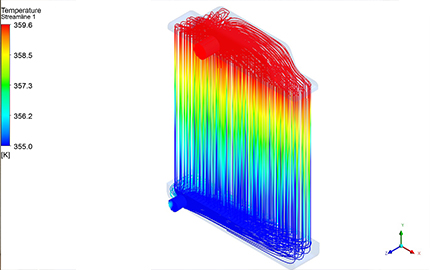

Solidworks Flowworks CFD sowftware and high performance workstations added to engineering department.

High speed welded tube mill to produce brass tubes for oil coolers, radiators and heater cores. Capacity is 100 meter per minute.

For high performance radiators, dimple unit was purchased for different tubes sizes.

Tube burst pressure test station purchased for OEM standards.